High Frequency Embossed Patches, Screen Printing Labels, and Heat Transfer Labels

At SHANHE GARMENT ACCESORIES CO.,LTD. We specialize in providing high-quality High Frequency Embossed Patches, Screen Printing Labels, and Heat Transfer Labels. Our products are customizable, durable, and perfect for various industries including apparel, sports, and corporate branding.

High Frequency Embossed Patches, Screen Printing Labels, Heat Transfer Labels)

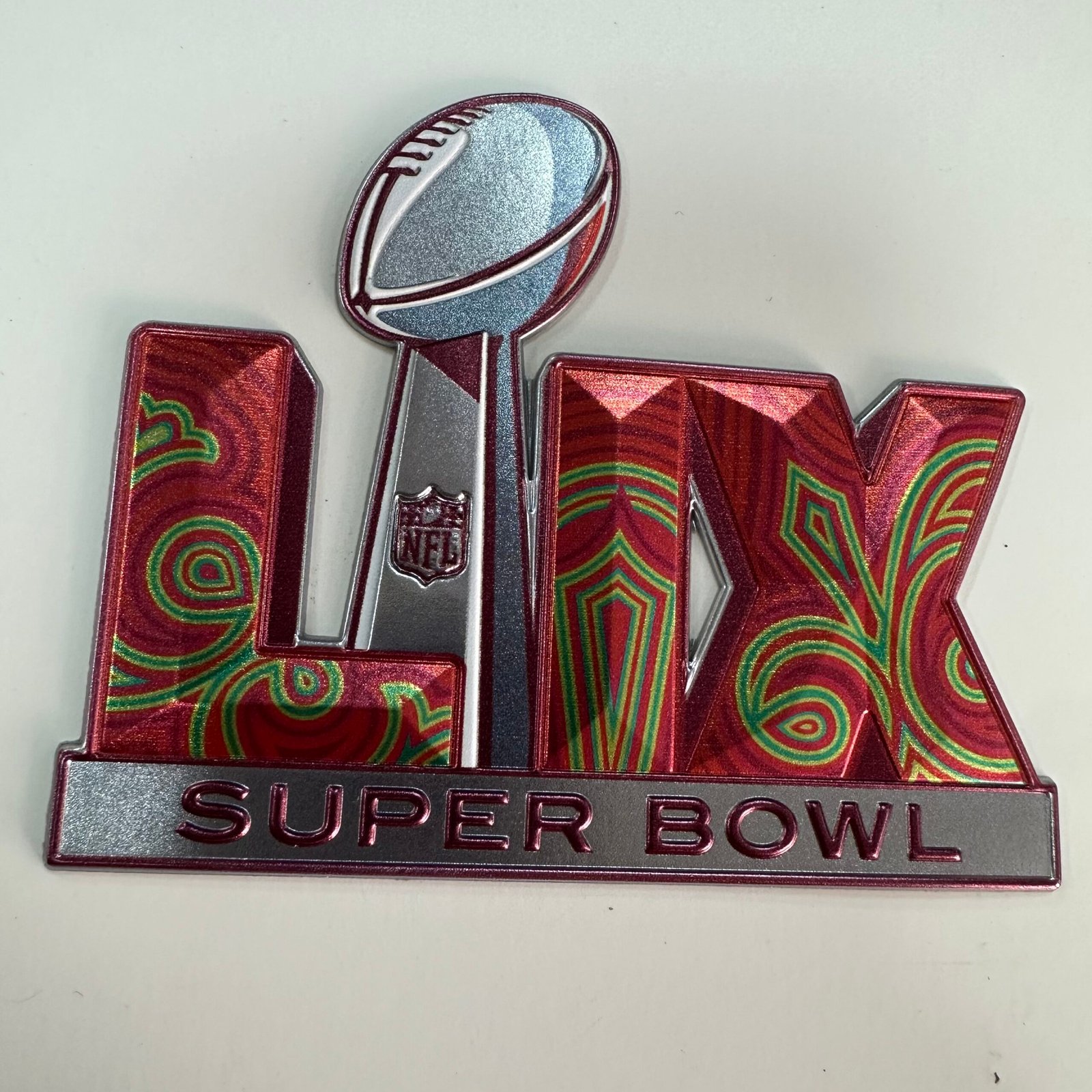

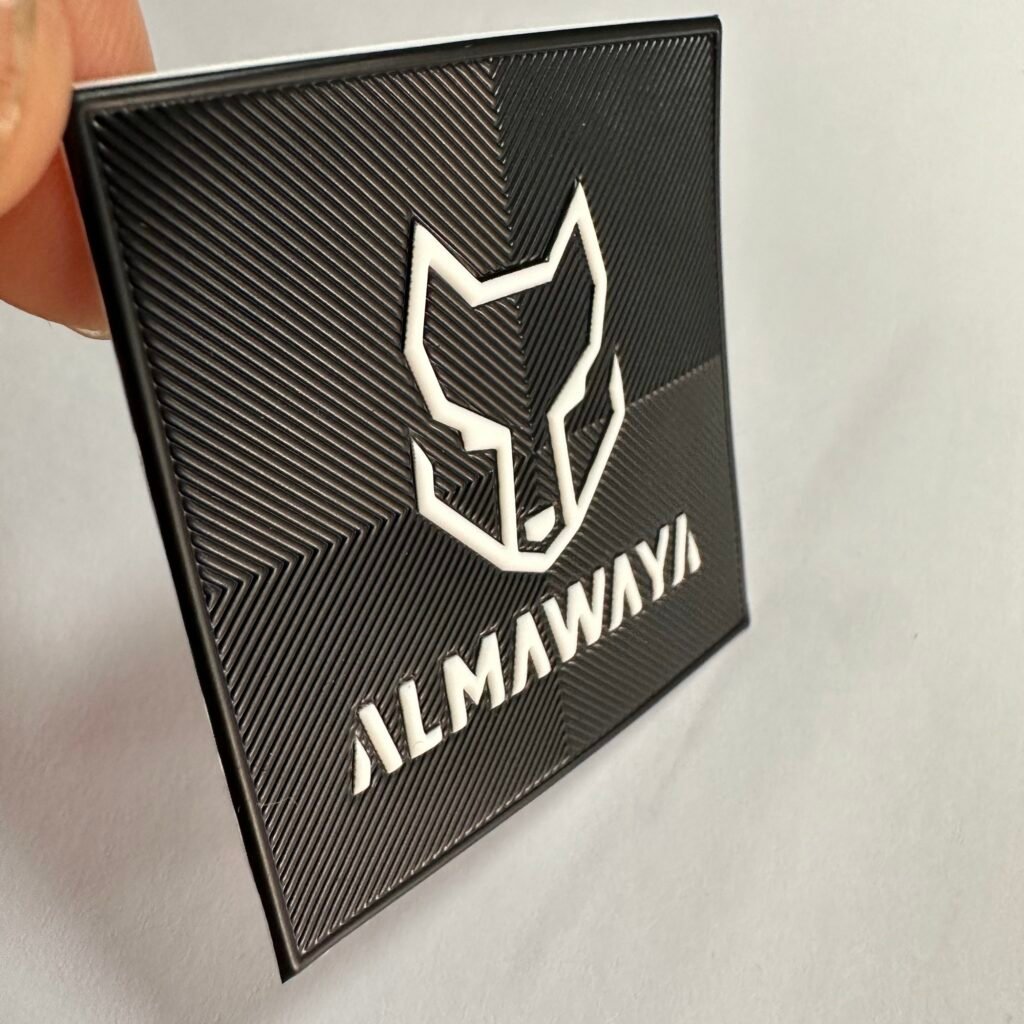

A. High Frequency Embossed Patches

High Frequency Embossed Patches are a premium choice for custom branding on jackets, hats, backpacks, and bags. These patches are crafted using PVC (polyvinyl chloride), a durable, waterproof, and weather-resistant material. As a result, they are ideal for outdoor gear such as camping equipment, covers, and outerwear.

Applications of High Frequency Embossed Patches

- Enhancing outdoor gear such as backpacks and jackets.

- Custom branding for team uniforms, corporate merchandise, and promotional items.

- Adding a professional touch to products used in sports, military, and recreational industries.

Applications of Transfer Labels:

Transfer labels are versatile and widely used in industries like fashion, uniforms, and sports. These labels ensure clean and precise branding on various surfaces. They are heat-applied, ensuring a seamless integration with fabrics, and are available in multiple finishes to suit your needs.

Why Choose High Frequency Embossed Patches?

High-frequency embossed patches are ideal for creating a bold, professional look on clothing and accessories. These patches offer durability and a refined finish, making them perfect for industries such as corporate branding, team sports, and promotional events. With customizable designs, you can add logos, patterns, or text that align with your brand identity.

- Exceptional Durability: Resistant to wear and tear, perfect for harsh environments.

- Customizable Designs: Available in a wide range of sizes, shapes, and colors to suit your branding needs.

- Weatherproof Material: PVC ensures longevity, even in challenging outdoor conditions.

High Frequency Embossed Patches are widely used by various organizations, including:

- Police Departments and Military Units

- Scout Groups and Outdoor Clubs

- Sports Teams and Corporate Branding Projects

- Fire Departments and Highway Patrol Units

How Can High Frequency Embossed Patches Be Applied?

These patches can be sewn directly onto garments or applied using Velcro backing, making them removable and reusable. Whether you’re looking for permanent or temporary branding solutions, these patches offer unmatched versatility.

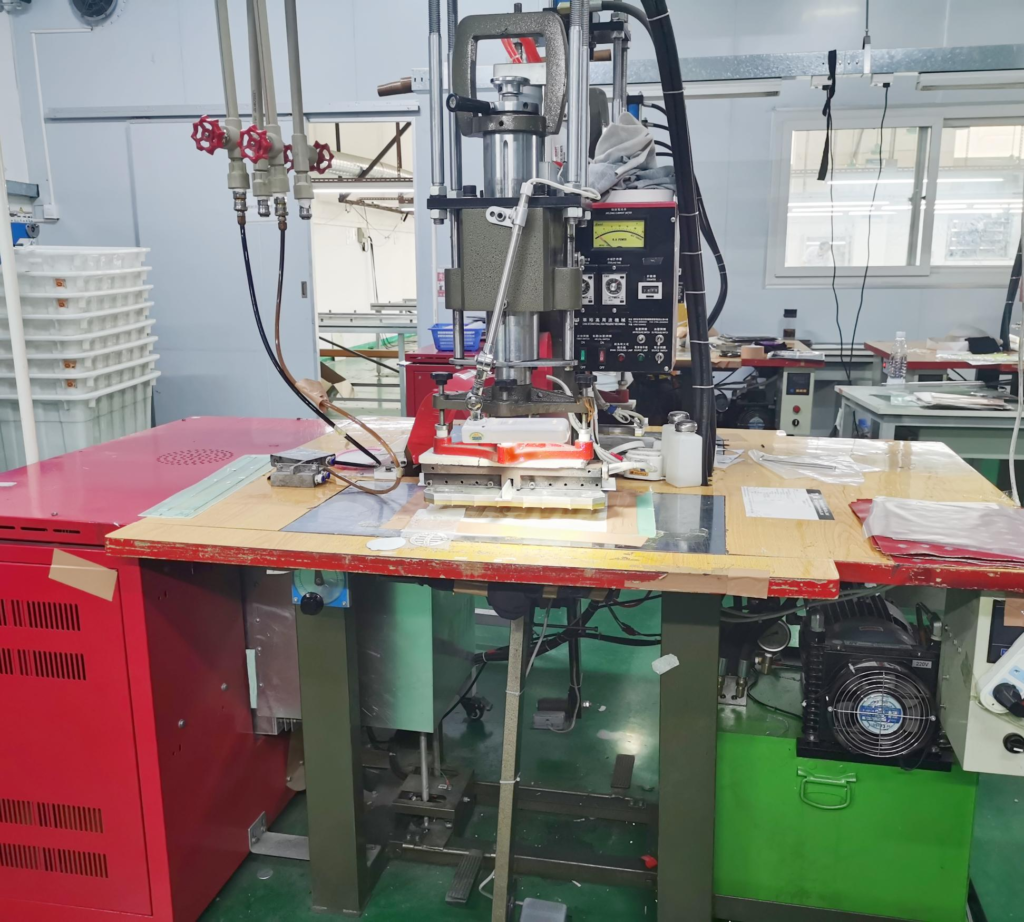

Video For High Frequency Embossed Patches Manufacturing

Our High Frequency Embossed Patches are created through a precise and innovative manufacturing process. Using advanced high-frequency machinery, we shape durable PVC material into custom designs, ensuring sharp details and long-lasting quality. This video showcases the entire production process, from material preparation to the final product.

Key Features of Our Process:

– **Precision Craftsmanship**: Each patch is meticulously embossed to achieve a clean, professional finish.

– **Durable Materials**: Weather-resistant PVC ensures your patches withstand the toughest conditions.

– **Customizable Solutions**: Tailored to your unique designs and branding needs.

Watch this video to discover how we bring your custom patches to life with high-frequency embossing technology.

High Frequency Embossed Patches Process

Step 1: Design & Material Preparation

Create custom designs and prepare premium PVC materials for high-frequency embossing. This step ensures precision and durability in every patch.

Step 2: High-Frequency Embossing & Cutting

Use advanced high-frequency technology to emboss and cut PVC patches with clean edges and detailed textures.

Step 3: Quality Checks & Packaging

Conduct thorough inspections to ensure flawless patches before securely packaging for delivery.

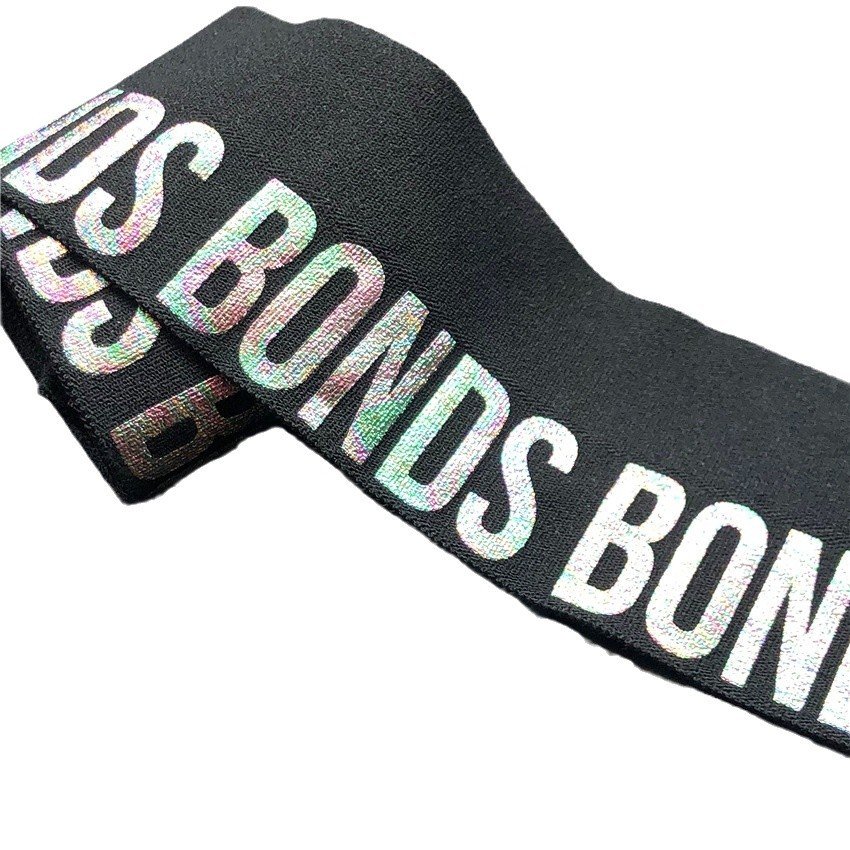

B. Screen Printing Labels&Heat Transfer Labels

PVC patches are perfect for jackets, hats, backpacks, and bags. Why? PVC (polyvinyl chloride) is a waterproof and weather-resistant material, and as a result PVC translates into wonderfully durable plastic patches. They are the alternative go-to for outdoor gear, such as camping equipment, covers and outerwear. As with all of our products, our pvc patches are custom-designed to your specifications.

Soft PVC patches are very popular for: police departments, military units, scout groups, highway patrols and fire departments, outdoor & sports such as airsoft, paintball, and hiking. They can be sewn on the garment equipment or they can have a Velcro backing if you don’t want your patches to stay permanent.

How Can Screen Printing Labels & Heat Transfer Labels Be Applied?

Screen Printing Labels:

Screen printing is applied directly onto the surface of the product. The ink is pressed through a fine mesh to create a smooth and vivid design. This process works best for flat surfaces like t-shirts, tote bags, and fabric tags.Heat Transfer Labels:

Heat transfer labels are applied using a heat press machine. The design is transferred from a backing paper onto the material through heat and pressure. This method ensures a smooth and professional finish, suitable for intricate designs.

Why Choose Screen Printing Labels & Heat Transfer Labels?

Screen Printing Labels

Screen printing labels are a cost-effective and versatile solution for branding and customization. They are ideal for products requiring detailed and vibrant designs.

- Vibrant Colors: Achieve bold, long-lasting prints with high color accuracy.

- Cost-Effective: Suitable for large production runs, offering excellent value for money.

- Versatile Applications: Perfect for various industries, including clothing, accessories, and promotional products.

Heat Transfer Labels

Heat transfer labels are a seamless and flexible branding option for products requiring smooth, tag-free designs.

- Soft and Tag-Free: Ideal for garments and textiles where comfort is a priority.

- Durable Designs: Resistant to washing and fading, ensuring long-lasting results.

- Customizable: Available in various finishes, including matte, glossy, or metallic.

Why Choose Our Labels?

Our Screen Printing Labels & Heat Transfer Labels are tailored to meet your specific needs:

- Customizable Options: Choose from various colors, textures, and finishes to match your brand.

- Durability Guaranteed: Resistant to wear, washing, and fading.

- Low Minimum Order Quantities (MOQs): Perfect for both small and large orders.

Video for Screen Printing Labels & Heat Transfer Labels Manufacturing

Our Screen Printing Labels and Heat Transfer Labels are manufactured using precise and advanced techniques to meet your branding and product customization needs. These videos showcase the key steps involved in the creation of these high-quality labels, ensuring a durable, professional finish.

Key Features of Our Process

- High-Precision Craftsmanship: Every label is created with detailed accuracy to ensure vibrant and consistent results.

- Durable Materials: Our labels are designed to withstand repeated washing, wear, and environmental conditions.

- Customizable Designs: Choose from a variety of colors, textures, and finishes to perfectly match your branding needs.

Screen Printing Labels & Heat Transfer Labels Process

Step 1: Screen Preparation & Design

Create high-quality screens and films for screen printing labels or prepare heat transfer films for application. This step ensures precision and clarity in every design.

Step 2: Printing & Transfer Application

For screen printing labels, vibrant inks are carefully applied layer by layer. For heat transfer labels, the design is seamlessly transferred to the fabric using heat and pressure.

Step 3: Quality Checks & Final Finishing

Thorough inspections are conducted to ensure durability, color accuracy, and flawless finishing. Final touches include packaging for secure delivery to your doorstep.

"Our High Frequency Embossed Patches Categories"

"Explore the Details of High Frequency Embossed Patches – Precision and Quality Close-Up"

“Discover the craftsmanship of our High Frequency Embossed Patches in this detailed video. See the fine embossed textures, vibrant colors, and durable TPU material up close. Ideal for uniforms, team logos, and premium branding solutions. Perfect for applications requiring long-lasting, high-quality patches. Contact us to create your custom embossed patches today!”

"Our Screen Printing Labels & Heat Transfer Labels Categories"

"Custom Velcro and Heat Transfer Labels for Functional Branding"

"Explore the Details of Screen Printing Labels & Heat Transfer Labels – Precision and Versatility Up Close"

“Take a closer look at the exceptional quality of our Screen Printing Labels and Heat Transfer Labels in this video. Observe the intricate printed details, smooth finishes, and seamless application on a variety of fabrics. Perfect for activewear, promotional items, and professional branding. Contact us to customize your labels with vibrant colors and durable materials today!”

How To Use Heat Transfer Labels

“Learn the step-by-step process of applying heat transfer labels with precision and ease. This video demonstrates how to properly align, press, and peel off the transfer sheet to achieve a flawless finish on fabric. Perfect for branding apparel, activewear, and custom clothing projects.”

Screen Printing Labels vs. Heat Transfer Labels

| Feature | Screen Printing Labels | Heat Transfer Labels |

|---|---|---|

| Appearance | Bold, vibrant, and slightly raised surface | Seamless, soft, and smooth with no raised edges |

| Best for | Flat surfaces like bags, tags, and team uniforms | Garments needing tag-free labels, such as t-shirts and activewear |

| Durability | Long-lasting, resistant to cracking and fading | Durable, resists washing and wear over time |

| Application Process | Ink applied through a screen using precise layering | Transferred onto fabric using heat and pressure |

| Cost Effectiveness | Ideal for bulk orders with larger designs | Great for smaller orders or intricate designs |

How to Choose the Right Label for Your Needs

Choosing between Screen Printing Labels and Heat Transfer Labels depends on your specific requirements:

- If you need bold, vibrant designs on flat surfaces, like tote bags, uniforms, or promotional items, Screen Printing Labels are your best choice.

- If comfort and a seamless look are priorities, such as for activewear, t-shirts, or high-end garments, Heat Transfer Labels are ideal.

- For small and intricate designs, Heat Transfer Labels offer better precision, while Screen Printing is more cost-effective for larger designs and bulk orders.